At R&G Metal Shaping we have been committed to technical excellence as part of our industrial DNA for years. One of the best examples of this commitment is our production plant dedicated exclusively to stainless steel. This space has been conceived not only to guarantee clean and precise work, but also to ensure that our customers in highly regulated sectors receive parts manufactured with the highest standards of quality, safety and reliability.

Specialized production in stainless steel, without risk of contamination

The decision to completely isolate this plant from the rest of the operations is no accident. Stainless steel, because of its hygienic properties, corrosion resistance and structural stability, requires a controlled environment free of any type of contamination.

In many industrial workshops, contact with other metals can lead to micro-contaminations that affect both the technical behavior of the material and its final appearance. In our plant, this risk does not exist. We have created an exclusive and segregated space, with internal protocols that guarantee that the stainless steel is worked impeccably, from the moment it enters our facilities until it is delivered to the customer.

This level of protection is not just a question of aesthetic quality: in sectors such as pharmaceuticals or food, metallic contamination can lead to safety problems, regulatory sanctions or even product recalls. Our specialized plant eliminates this risk at source.

Welding with precision, not in a hurry

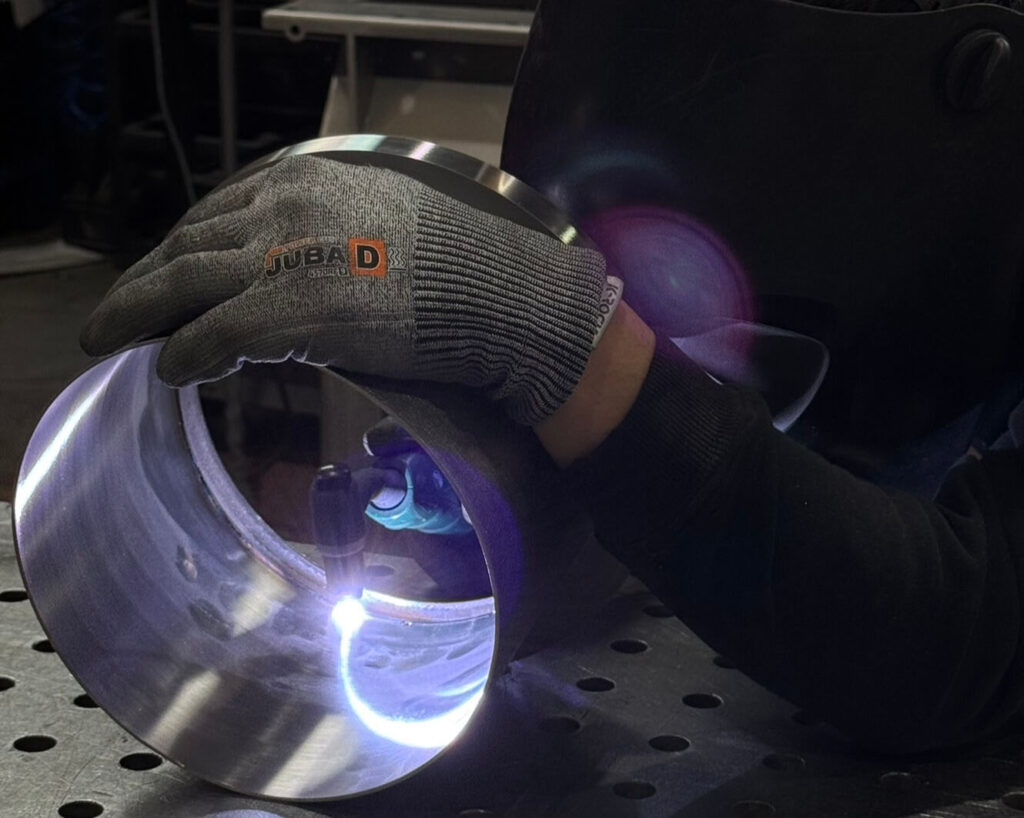

Within this environment, we develop a complete range of industrial processes focused on stainless steel transformation. The plant is equipped with TIG and MIG welding stations, as well as laser welding technology, ideal for high precision work and minimum thermal deformation.

The team working in this plant is highly qualified and operates under a rigorous results-oriented methodology. . This allows us to offer agile solutions, adapted to every need, always keeping the technical requirement as a reference.

The plant is not only efficient: it is also flexible. We adapt to both complex projects and short production runs with tight deadlines, without ever losing control over the quality of the final product.

We don't talk about quality: we certify it

In an industry where everyone promises quality, we prove it with facts and certifications. All the processes of our specialized plant are endorsed by internationally recognized standards, which ensure both legal compliance and technical excellence.

We comply with EN 1090, an essential standard for the manufacture of metal structures in Europe, which requires total control over the execution and materials. We also work under the criteria of ISO 3834, specific for welding processes, which guarantees that our procedures are technically validated and documented. And, of course, our products include the CE marking, which certifies their conformity with the essential safety and performance requirements demanded by the European Union.

IN 1090

ISO 3834

Designed for industries that demand the utmost

The R&G Metal Shaping stainless steel plant is not for everyone: it is designed to meet the needs of sectors where technical requirements, material hygiene and process traceability are non-negotiable.

In the pharmaceutical industry, we manufacture components and structures that must maintain absolute sterility and cleanliness, even after years of use. In the food sector, our parts are designed to come into contact with sensitive products without altering their properties or jeopardizing consumer safety.

In the aerospace field, we work with very tight tolerances and quality controls that guarantee structural reliability under extreme conditions. And in the defense sector, we provide metallic solutions with a level of strength and durability that must be backed by exhaustive certification and testing.

This plant is not just a physical space; it is a reflection of how we understand our work. We are committed to stainless steel with the firm conviction that specialization, when accompanied by knowledge, technology and method, generates a real differential value for the customer.

Do you work with stainless steel and need a reliable technical partner?

At R&G Metal Shaping, we put technique, method and commitment at the service of what matters most: doing it right.