The key to our results

At R&G Metal Shaping, we take pride in providing our customers with state-of-the-art industrial ironwork services. One of the key technologies that we use to ensure accurate and efficient results is the use of CAD/CAM (computer-aided design / computer-aided manufacturing). Today, we will explore in detail how CAD/CAM models play a key role in our metal forming process and how they benefit our customers.

What are CAD/CAM models?

CAD/CAM models are accurate and detailed digital representations of the parts to be manufactured. Using advanced computer-aided design software, our engineering experts create, modify and optimize 2D or 3D models that serve as a reference for the entire manufacturing process.

Differentiating CAD from CAM, we find that the former is focused on the software that allows us to design the parts in 2D/3D from our technical office, while CAM is focused on the connection between the computer and the machine that will create the previously designed parts. The combination of the two models is fundamental for industrial automation, guaranteeing quality and efficiency.

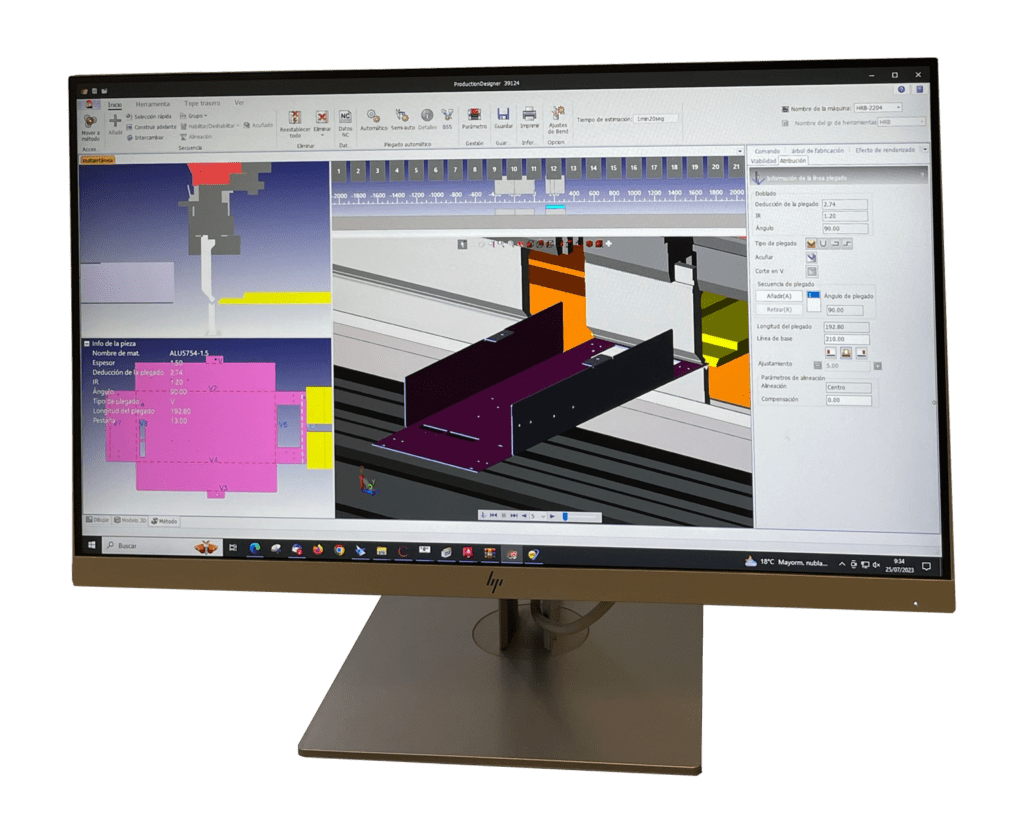

Model CAD/CAM designed for a bending process. Guaranteeing perfection in every bend.

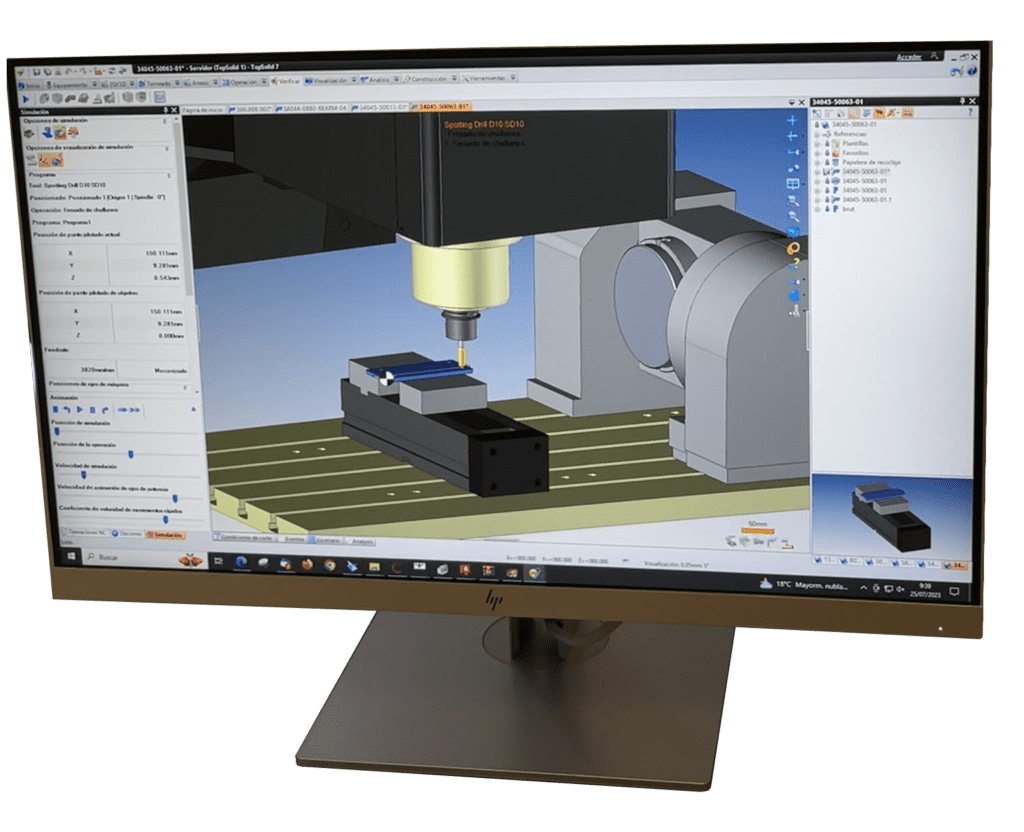

Model CAD/CAM designed for a precision machining process, guaranteeing perfect parts.

Benefits of the CAD/CAM models in R&G Metal Shaping:

- Accuracy and consistency: The models we design allow us to achieve exceptional accuracy at every step of the metal forming process. By working with exact measurements and meticulous detail in the digital design, we can accurately replicate the desired parts time and time again, ensuring consistency in the quality of our products.

- Performance Optimization: Through analysis and design techniques, CAD/CAM models allow us to improve and optimize the performance of existing parts. We can identify areas of improvement, perform simulations and adjust the design to achieve better performance and efficiency based on our customers' specific needs.

- Design flexibility: They give us great flexibility in the customization and adaptation of metal parts. We can digitally adjust and modify designs to meet the specific requirements of each project, allowing us to offer tailor-made solutions and respond to the individual demands of our customers.

- Time and cost savings: The use of CAD/CAM models significantly speeds up the manufacturing process. By working with digital designs, we can reduce the time needed to make changes, optimize production and minimize errors. This translates into time and cost savings for our customers, as well as faster and more efficient delivery of orders.

- Clear communication and prior visualization: These models facilitate clear communication between our sheet metal experts and our customers. By previewing digital designs, customers can better understand how finished parts will look and provide early feedback. This ensures that we are aligned with expectations and allows us to make adjustments prior to manufacturing.

At R&G Metal Shaping, the implementation of CAD/CAM models in our metal forming process allows us to deliver accurate, customized and efficient results to our customers. This advanced technology ensures high quality production, increased design flexibility and clear communication throughout the process. We are committed to the continued adoption of innovations such as the CAD/CAM models to provide the best service and highest quality in industrial sheet metal forming.