Reverse engineering is a process by which an object is analyzed and broken down to obtain detailed information about its structure, materials, function, and manufacturing processes. This process is used to understand how an object works, to replicate it, or to improve its performance.

At R&G Metal Shaping we offer a reverse engineering service for those projects in which it is necessary to replicate or improve existing parts, either because the plans have been lost or because you want to optimize their performance.

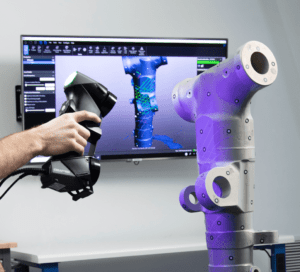

At R&G Metal Shaping we offer a comprehensive reverse engineering service, which includes from the analysis and design to the manufacturing and verification of the part. We have a team of highly qualified professionals with a wide experience in the sector, as well as the tool of the 3D Laser Scanner and advanced software to carry out the process accurately and efficiently.

In short, our R&G Metal Shaping reverse engineering service is the perfect option for those projects that require replicating or improving existing parts, with the guarantee of a professional team, advanced technologies and high-quality final results.

Our service reverse engineering is used in a wide variety of industries to guarantee the quality of all our services in:

Whether it is a small or large project, we have the necessary means to make it a reality.

Contact us for a first consultation.