We are pleased to announce that R&G Metal Shaping will be present on May 17,18 and 19 at FEINDEF!

At FEINDEF, we will have the opportunity to showcase our latest services, connect with other industry leaders and learn about the latest trends and innovations in the sector.

What is FEINDEF?

FEINDEF is one of the most important trade fairs in Europe in the defense sector and security, and this year has 40,000 m² of exhibition space, an attendance of more than 450 exhibitors from 20 countries and 100 foreign delegations. In its last edition, held in 2021, the fair received more than 15,000 visitors from 57 different countries.

In this edition there will be many new features, new programs, products, initiatives, surpassing the figures of the previous edition. In addition, this year has been a record, more than 400 companies from 25 countries have already booked their space in FEINDEF, representing 100% of the total space.

The fair is also an important forum for the presentation of new technologies and products, and live demonstrations of defense and security systems can be seen at the fair.

In addition, FEINDEF has a program of conferences and round tables that address relevant topics for the industry, such as cybersecurity, technological innovation in defense or the role of the armed forces in the prevention of natural disasters.

Why will R&G Metal Shaping be at FEINDEF?

As a company specialized in the manufacturing of high precision metal parts and components, R&G Metal Shaping will highlight its custom engineering and manufacturing services for the sector aerospace and defense at the FEINDEF fair.

In particular, some of the services that R&G Metal Shaping will highlight are:

1. Design and manufacture of custom parts and components: R&G Metal Shaping has a team of highly trained and experienced engineers who can design and manufacture high precision metal parts and components to customers' specifications and needs. These parts and components can be used in defense systems and other critical equipment.

2. Advanced manufacturing processes: The company uses state-of-the-art technology and advanced manufacturing processes to ensure the precision and quality of its parts and components. These processes include laser cutting, forming, machining, robotic welding, manual welding (TIG, MIG), laser welding, among others.

3. Rigorous quality control: R&G Metal Shaping has a rigorous quality control process at every stage of manufacturing, which uses 3D laser scanner to issue a 100% verification report of the dimensions. Following the requirements of EN9100 standards for aviation, special and defense requirements, along with ISO9001 for quality assurance.

4. Technical advisory services: In addition to manufacturing metal parts and components, R&G Metal Shaping also offers technical consulting services to its customers. The company's team of engineers can advise on material selection, part and component design, and other critical aspects of the manufacturing process.

In summary, R&G Metal Shaping could highlight its expertise in manufacturing high precision custom metal parts and components for the aerospace and defense industry, its use of advanced technology and high quality manufacturing processes, and its rigorous quality control process to meet the industry's most demanding requirements.

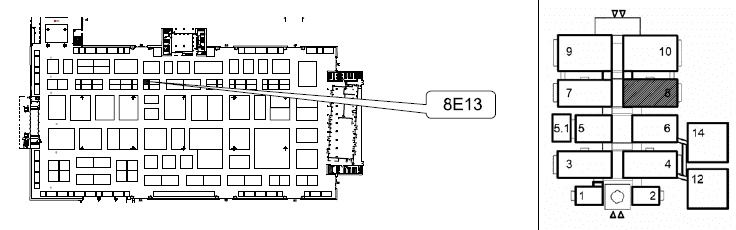

If you are attending FEINDEF, we invite you to visit our booth 8E13 and learn more about R&G Metal Shaping.

We look forward to connecting with you!