At R&G Metal Shaping, we embark on this new year with enthusiasm, renewed energy and dedication to offer industrial ironwork services with the same or higher quality than before, ready to stand out even more in the industry.

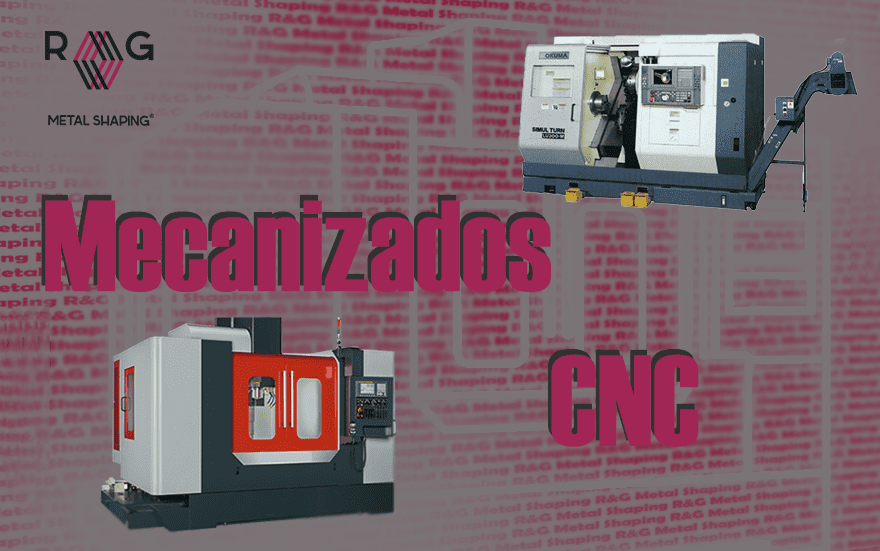

However, today we would like to introduce you to our CNC machining services with our commitment to quality and precision, which remain unwavering.

What does the CNC machining service consist of?

CNC machining service is a fundamental technique in the manufacture and production of metal components, where machines and tools are used to shape and design precision parts. This process involves the removal of material from a blank part to obtain a desired shape, and can include operations such as milling, turning, drilling, among others. Precision and customizability are key features of machining, allowing the creation of unique and complex parts for various industrial applications. In short, machining services play a crucial role in the creation of precise, customized metal components.

A Short History of Machining and the Revolution CNC:

Machining has come a long way since the first manual lathes and milling machines. The introduction of numerical control in the 1950s marked a milestone, but it was with the advent of Computer Numerical Control (CNC) in the 1970s that the game changed completely.

The implementation of the CNC not only improved accuracy, but also significantly reduced production times. The machines could now follow precise instructions, translating complex designs into reality with astonishing speed and efficiency.

Our machines for machining service CNC:

- Conventional vertical milling machine CNC 1.500×400 mm.

- CYCLONE 5-axis machining center.

- OKUMA 300 mm high production lathe.

- Conventional lathes of 400 mm and 250 mm.

- Radial drilling machine

- Threading machines and foot drills

Machines and features to be highlighted:

CNC Okuma Simul-Turn LU300-M lathe: This CNC turning master ensures precise operations on metal parts, with a numerical control that brings efficiency to its peak.

CYCLONE 5-Axis Machining Center: An engineering marvel that enables the manufacture of parts with three-dimensional movements, taking versatility to new heights.

Why Are Our Machines Essential?

Unmatched Versatility: From milling complex parts to precise turning, and from meticulous drilling to seamless tapping, our machines are experts at multitasking.

Efficient Automation: With the computerized numerical control (CNC), automation takes the helm. Operations programmed for precise and consistent execution, far surpassing manual techniques in terms of speed and consistency.

TopSolid program and CAD/CAM: 3D simulation with TopSolid not only ensures the feasibility of the design, but also allows the creation of customized parts that meet the specific needs of each customer.

Benefits of our CNC Machining Service:

Unmatched accuracy: The CNC machines operate with precision that goes beyond manual capabilities, delivering consistent results.

Efficient Production: Automation reduces production times, allowing faster part manufacturing without sacrificing quality.

Total customization: Thanks to programs such as TopSolid, each part can be unique, adapting exactly to the needs of each customer.

This year, at R&G Metal Shaping, we will advance machining excellence. From precise projects to custom parts, we are here to raise your expectations and offer you solutions that will define new standards in the industry.