In the field of metal forming and welding services for joining metals, the welding stands out as an essential technical art. Among the various welding techniques, TIG, MIG, MMA and Laser welding are the ones that stand out for their efficiency, precision and adaptability. At R&G Metal Shaping, we have perfected these techniques and, as a testament to our dedication, we hold a ISO certification that supports our commitment to excellence.

What is TIG, MIG, MMA and Laser Welding service?

MMA (Manual Metal Arc): Also known as stick welding, it is one of the oldest and most versatile methods, where the heat source comes from an arc formed between the base metal and the electrode.

MIG (Metal Inert Gas) and MAG (Metal Active Gas)These welding processes use an electric arc established between a consumable electrode (wire) and the piece to be welded. This arc is shielded with a gas or gas mixture that prevents contamination of the weld bead. While MIG uses inert gases to weld non-ferrous metals, MAG welding services are used with active gases for steels and other ferrous metals.

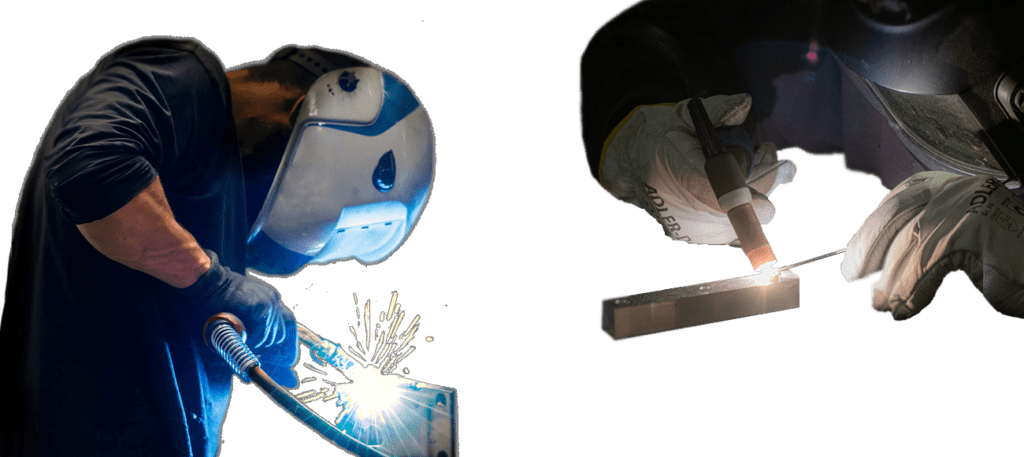

TIG (Tungsten Inert Gas): This process uses a non-consumable tungsten electrode and the filler material is introduced manually. It is highly precise and is especially used for thin metals and welds that require high quality finishes.

Laser: is a process that uses a concentrated laser beam as a heat source to fuse two pieces of metal together. This process is known to be highly efficient, capable of producing high quality welds at a much faster rate than other conventional methods. In addition, because the heat-affected area is very small, deformation and stress on the welded parts are minimal, resulting in stronger, cleaner joints.

How it is used:

Each technique in welding services has its own methodology. For example, in MIG welding, a gun is used to feed the wire and release the shielding gas. In TIG, the filler material is fed manually while controlling the arc with a foot pedal. In MMA, a coated electrode is used which is consumed as the welding progresses. Finally, Laser is a beam of laser light to join two metallic materials.

Our ISO Certification in welding services:

At R&G Metal Shaping, we strive to ensure that every welding service meets the quality standards highest standards. That is why we have obtained a specific ISO certification for our welding processes. This certification not only validates the competence and skill of our welders, but also guarantees that the procedures and equipment we use meet international standards. It is proof of our commitment to excellence and an additional guarantee to our customers that every weld performed at R&G Metal Shaping is of the highest possible quality.

Whether TIG, MIG, MMA or Laser, at R&G Metal Shaping we master these welding service techniques, guaranteeing strong and durable joints. We continue to invest in training and technology to provide optimal solutions to our customers. So, whether you require a robust structure or a detailed finish, you can rely on the expert hands at R&G Metal Shaping to deliver exceptional results.