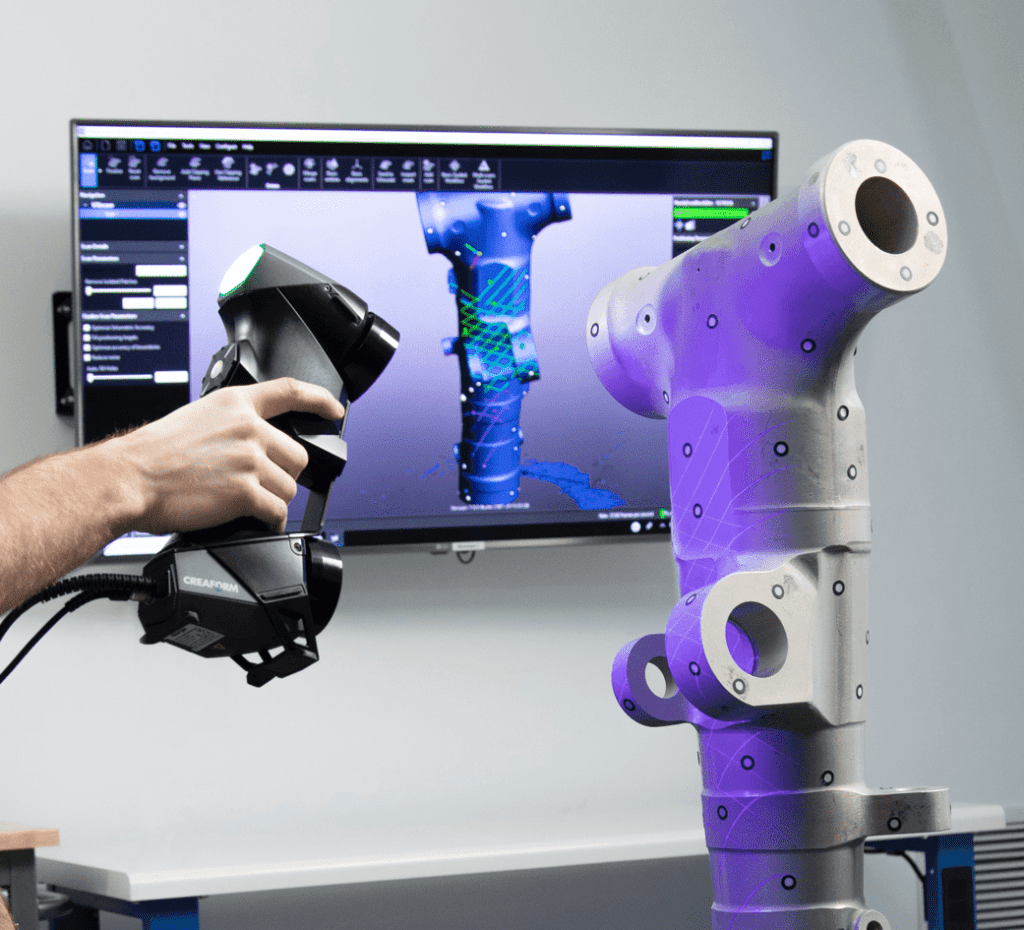

At R&G Metal Shaping we have implemented the 3D laser scanner, using a scanner HandySCAN 3D. It is a technology used in industrial ironwork to capture precise three-dimensional data of objects and surfaces, providing great advantages to our company.

How does the 3D laser scanner work?

Structured light projection: The HandySCAN 3D scanner projects a structured light, usually a series of fringe or grid patterns, onto the surface of the object to be scanned.

Data Capture: The structured light reflects off the object and is detected by the scanner's cameras. These cameras capture the variations of the projected light, which makes it possible to measure the distance and shape of the object based on the displacements of light.

Data processing: The data captured by the HandySCAN 3D scanner is processed using specialized software. The software combines information from the cameras, projected light patterns, and recognition algorithms to generate a digital three-dimensional model of the scanned object.

Calibration and registration: During the scanning process, it is important to calibrate the scanner to obtain accurate measurements. Also, if multiple parts of the object are being scanned, a registration must be made to correctly align the different scans and generate a coherent model.

How we use 3D scanning in industrial sheet metal services

Design and development of products: 3D laser scanning is used to capture the geometry of existing parts or prototypes and convert them into digital models. These models can be used to make design modifications, create molds or dies, and perform virtual simulations.

Quality control and process assurance: 3D laser scanning allows you to compare scanned parts with CAD models or original specifications to verify quality and detect deviations. This helps identify defects, perform dimensional inspections, and ensure the accuracy of manufactured products. Then the 3D scanner becomes an essential tool to maintain our Quality commitment.

Repair and Maintenance: By scanning damaged or worn components, accurate 3D models can be created for the development of replacement parts. This speeds up the manufacturing process and ensures better fit of replacement parts.

Reverse engineering: 3D laser scanning is used to perform reverse engineering for the manufacturing of products. An existing part can be scanned and used as a basis to generate an accurate CAD model, making it easy to reproduce or improve the design.

Documentation and archive: 3D laser scanning allows you to create a complete digital representation of objects and components in the sheet metal shop. This provides an accurate and detailed digital file that can be used for historical tracking, technical documentation and version control.

In short, 3D laser scanning with the HandySCAN 3D scanner is a versatile tool for manufacturing industrial products. It provides precise and detailed measurements of objects and components, aiding in design, quality inspection, and reverse engineering. By taking advantage of this technology, we can improve the efficiency of our processes, reduce costs and guarantee the quality of services.